Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: Plastic Rapid Prototype

Brand: TEAMWORK

Standard: Other

Surface Treatment: Other

Energy Source: Other

Material: Other

Small-Lot Production: Available

Packaging: Carton box + Wooden case

Transportation: Ocean,Air,Express

Place of Origin: China

Certificate: ISO 9001

Port: Shenzhen,Guangzhou,Rongqi

Payment Type: T/T,Paypal,Western Union

Incoterm: FOB,EXW

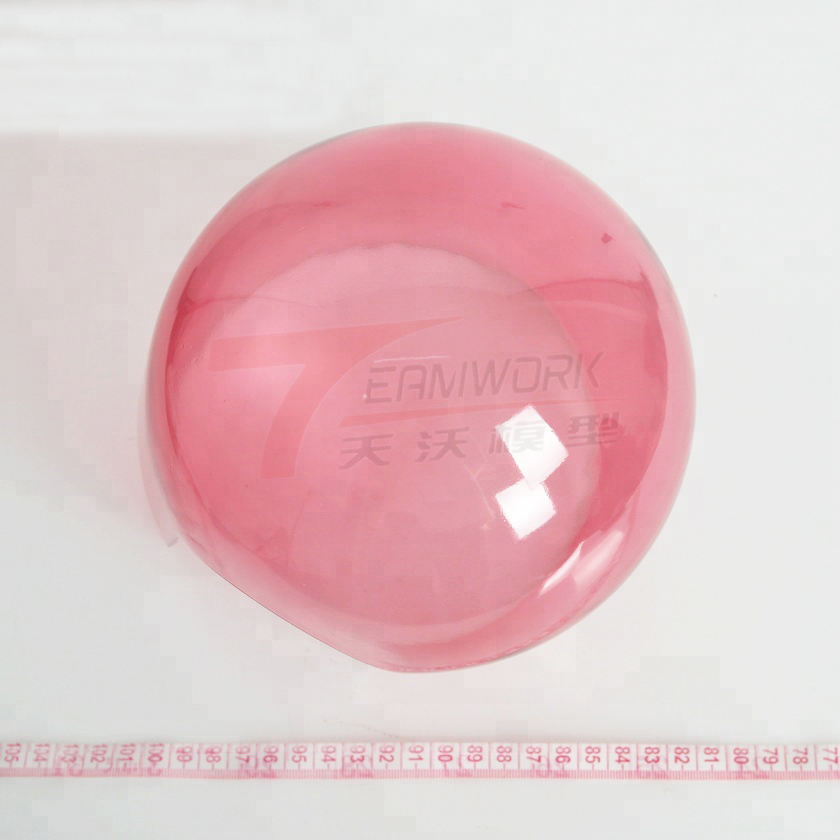

Vacuum Casting technology for acrylic prototype producing.

Vacuum casting: It is a process specially used for making delicate prototype models and small batch replication. It is widely used for proofing preview of injection products. The Plastic Materials commonly used in vacuum casting are PP and PA. The color selection and strength of molded parts are highly flexible, which is very suitable for product designers to customize products.

1. Process cost: processing cost (low), unit cost (medium).

2. Typical products: prototype models, consumer electronics, sports equipment, toys, etc.

3. The output is suitable: suitable for single-piece customization and small batch production.

4. Quality: The surface of the product is precisely molded, but the volume will be reduced by 3% after molding.

5. Speed: Determined according to part size (45 minutes-4 hours / piece).

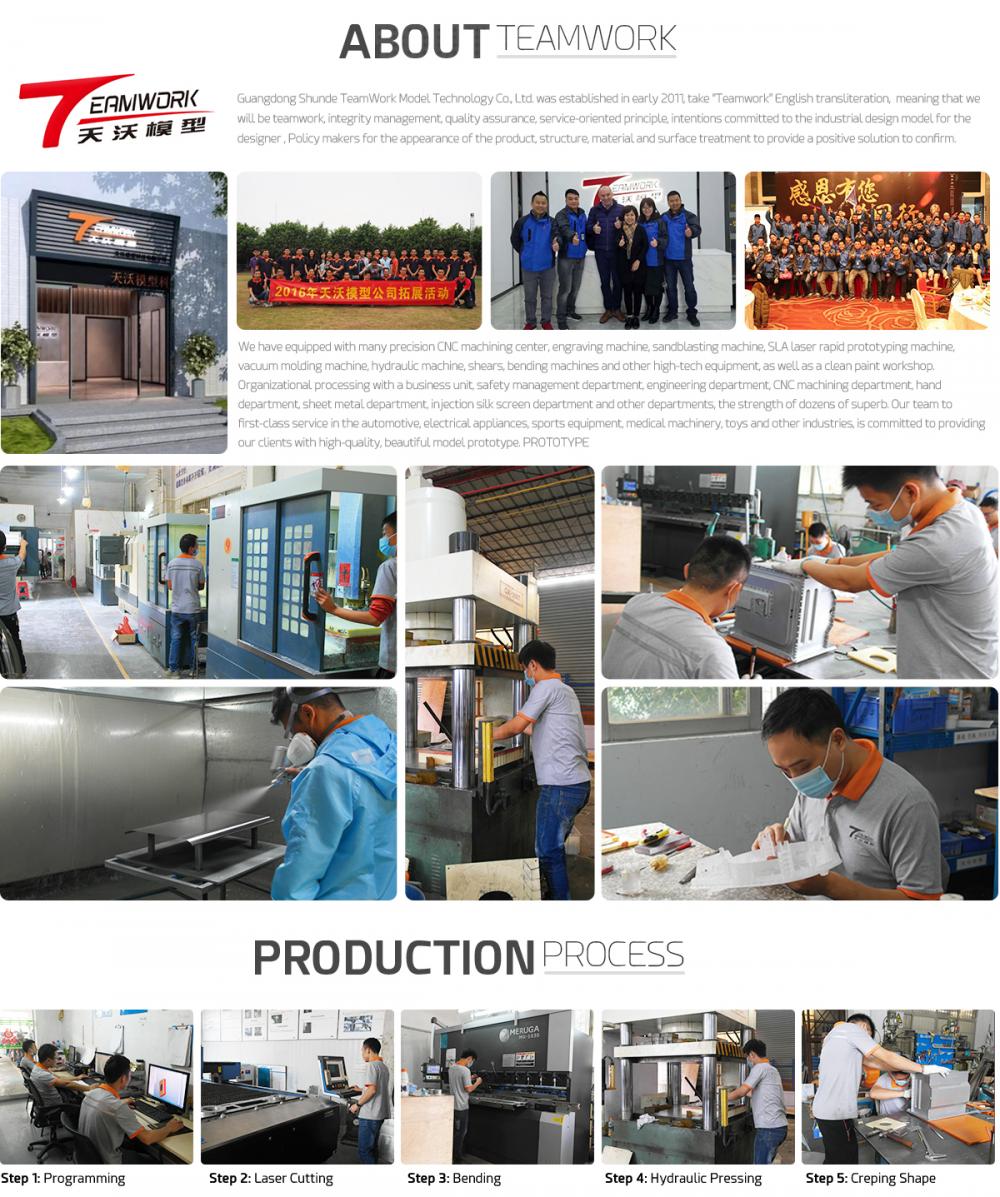

As a professinal Rapid Prototype services provider, we support technologies of rapid prototype: CNC Machining, turning, milling, drilling, bending, stamping, pulling, welding, laser cutting, vacuum casting, 3D Printing, reaction Injection Molding, and so on.

HOW TO COOPERATE?

Step 1: Email us your drawing.

Step 2: Get quotation sheet and arrange deposit.

Step 3: Processing manufacture.

Step 4: Delivery after got balance payment.

Product Categories : Technologies Services > Vacuum Casting

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.